Label Applicator Machine Failures: Real Case Studies and Engineering Lessons

- PrintMach

- Sep 12, 2025

- 2 min read

Updated: Sep 18, 2025

In packaging automation, label applicator machines sit at a critical point in the production line. When they fail, the impact isn’t just cosmetic- it can mean wasted material, increased downtime, and even costly product recalls.

Below are real-world labeling machine failures, their root causes, and the engineering lessons that can help prevent them.

1. Label Tearing Due to Misalignment and Weak Liner

Case: Food Packaging Company (AutoMate)

A large food packaging line reported labels tearing during application. Initially, it was suspected to be an adhesive issue, but engineers traced it back to two combined problems:

The applicator head was misaligned with the conveyor system.

The label liner material was too weak for the operating speed.

Once the applicator was realigned and a stronger liner material was used, the tearing stopped immediately.

Engineering takeaway:

Regularly audit label applicator alignment, especially after installation or maintenance.

Match liner tensile strength to line speed.

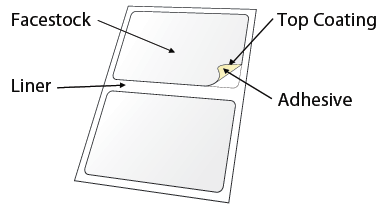

Treat labels as part of the label application process, their mechanical properties matter in high-speed production.

[Source: AutoMate Labels – Case Study]

2. Backing Paper Breakage from Die-Cutting and Tension Issues

Case: MI Labels- Failure Analysis

In another case, rolls kept snapping mid-run. Engineers conducted a structured failure analysis and found multiple causes:

Cracks at roll edges due to poor handling.

Excess rewind tension, causing adhesive bleed and sticking.

Over-aggressive die-cutting pressure, weakening the release liner.

Silicone release layer damage, reducing peel strength.

Engineering takeaway:

Establish strict roll handling protocols, edge cracks often start in storage.

Calibrate die-cut settings carefully: too deep weakens the liner, too shallow causes poor release.

Balance rewind tension to avoid liner stress.

[Source: MI Labels – Failure Analysis]

3. Liner Tears at High Speed: Silicone Coating Voids

Case: High-Speed Auto-Applicator Lines

Some plants reported liner tearing shaped like “V” notches. Investigation revealed the root cause: silicone voids in the coating of SCK (Super Calendared Kraft) paper liners.

The fix was switching to PET liners, which offer higher tensile strength and fewer coating defects.

Engineering takeaway:

For high-speed label applicator machines (300+ BPM), PET liners are more reliable than paper liners.

Always include liner surface coating analysis in labeling machine troubleshooting.

[Source: EMP4Labels – Liner Tear Analysis]

These case studies highlight how label applicator machines are more than just “sticker placers.” Each failure, from liner tears to misapplied labels, points to deeper engineering challenges in material choice, machine setup, and preventive maintenance!

By learning from real-world labeling machine failures, engineers can design and operate more reliable packaging automation systems by reducing downtime, saving costs, and protecting brand integrity.

.png)

Comments